From the left, Shawn DeLorey, lead four-color web press operator; Rick Dunn, executive vice president; John Galligan, president; and Mike Daugherty, pressroom manager; oversaw and implemented the breakthrough LED-UV technology usage on a high-speed web offset press.

via Printing Impressions by Mark T. Michelson

As the six industry leaders chosen as our “2023 Innovators of the Year” illustrate, the successful pursuit of innovation can manifest itself in many areas within organizations. Applying new processes, introducing new techniques and technologies, achieving complete employee buy-in, and establishing successful ideas creates new value propositions — for companies, their employees, and especially their clientele.

Take Newburyport, Massachusetts-based Bradford & Bigelow (B&B). Led by John Galligan, the 8.5×11″ educational workbook manufacturer is bucking conventional industry wisdom by being the leader in a target market, and not trying to diversify beyond that. That singular niche enables B&B to laser-focus on its production efficiencies, including its trail-blazing LED-UV web offset technology adoption. B&B also financially rewards and honors its employees on a “Wall of Fame” for their suggestions that boost productivity and quality, and simplify workflows.

“Innovation is part of our DNA,” says John Galligan, president of educational book printer Bradford and Bigelow (B&B). Galligan is also a big fan of anthropologist Charles Darwin who stated, “It is not necessarily the strongest or smartest species that survives. It is the one that is most adaptable to change.”

“At B&B, we adjust to change and embrace continuous improvement in everything we do — whether it is equipment, technology, marketing, or HR policies,” Galligan notes. “Sadly, there are a lot of legacy companies no longer with us who did not adapt to changing markets and technology.”

Early on, B&B’s prime markets were computer manuals, financial printing, and secure testing. However, as those markets declined and migrated online, Galligan focused all of B&B’s CapEx and marketing efforts to the 8.5×11″ educational workbook market for K-12, home-schooling, and faith-based publishers. He recognized the workbook model was user-friendly to students and parents who could do the homework, tear out the perforated pages, and turn in the assignment the next day. Workbooks have a lifespan of 5-10 years, need to be reprinted every year, and provide a source of recurring revenue. For most educational publishers, the workbook model is more profitable than the online model.

The COVID-19 pandemic also grew the market. More students opted out of public schools, standardized test scores plummeted, and then the American Rescue Plan Act provided school districts with millions of dollars to counteract the declining test scores. B&B anticipated these market shifts and adjusted accordingly.

A 2022 inductee into the Printing Impressions Printing Industry Hall of Fame, Galligan also correctly anticipated the dramatic shift from one- and two-color to four-color workbooks. “4C printing is more expensive, but much more graphically appealing to the students,” he says. “And the cost of the paper, binding, and cover printing is all the same.” B&B’s highly focused product line and innovation initiatives tie in nicely with its ISO 9001:2015, G7, and 5S quality and continuous improvement programs. A case in point is the recent completion of two challenging and expensive manufacturing projects that are not only driving B&B forward, but also benefiting the industry at large.

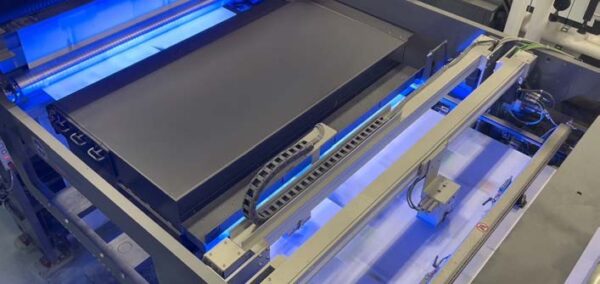

This 5 foot LED/UV drying unit replaces a 40 foot oven and chill rollers with no natural gas consumption, no VOC emissions, and less paper waste.

B&B’s highly focused product line and innovation initiatives tie in nicely with its ISO 9001:2015, G7, and 5S quality and continuous improvement programs. A case in point is the recent completion of two challenging and expensive manufacturing projects that are not only driving B&B forward, but also benefiting the industry at large.

B&B recently celebrated the startup of the first 48-page, four-color manroland Goss Lithoman LED-UV web offset press in the world — an environmental and economic game-changer for the entire industry. The press incorporates Baldwin/AMS LED-UV technology, which in turn eliminates all VOC emissions, reduces natural gas consumption and paper waste, and enables a 40-ft. reduction in the press length compared to a traditional heatset web offset press.

Additionally B&B upgraded its pair of 48-page Timson Zero Makeready book presses with 30 new motors and drives on each press. The company served as the North American beta site for Amerikal/Timson, which worked with the B&B team to successfully integrate the old and new systems. “The upgrades greatly extend the useful life of these presses another 20 years, making them more energy efficient, productive, and providing enhanced safety features,” Galligan points out. “These upgrades are now being done by Amerikal on the fleet of Timson presses all over North America.”

B&B also embraces smaller, incremental improvements and innovations. The company’s SCREEN inkjet presses are equipped with in-line drilling, as is its Muller Martini Alegro perfect binder, and boxing is completed as an in-line process. “We believe in one and done,” notes Galligan about the more efficient workflow in comparison to multi-step, off-line finishing processes.

Investing in the Future

The $100+ million company operates out of 140,000 sq. ft. of manufacturing space with 200 employees, making its sales per employee ratio the envy of many other book manufacturers. Part of that success has been derived by the major capital equipment investments during the past three years to maximize productivity and automation. A $15+ million expansion in 2019 included the installation of a 48-page, four-color manroland Goss heatset web press, upgrades to a pair of SCREEN Truepress Jet520HD inkjet web presses with in-line finishing, a 50,000-sq.-ft. plant expansion, as well as the addition of 50,000 sq. ft. of warehousing space in nearby Seabrook, New Hampshire.

That was followed in 2021 with another $20+ million investment in the installation of an HP PageWide T490 inkjet web press coupled with an in-line Muller Martini SigmaLine finishing system; a Muller Martini Alegro perfect binder; an additional 150,000 sq. ft. of warehouse space in Newton, New Hampshire; and an order for a second four-color manroland Goss 48-page web offset press.

“Although we always measure twice and cut once, we embrace change when it comes to making major capital equipment investments,” stresses Rick Dunn, B&B executive vice president. “We embrace calculated risk.”

Innovative HR Policies and Company Culture

B&B also realizes a company is only as good as its workforce — and Galligan and his management team devote considerable effort and provide monetary rewards toward employee development, training, and retention. That was certainly apparent during the pandemic. Rather than reductions in staff, wages, and hours, B&B took a different track. To show their appreciation, all manufacturing employees received $2-per-hour wage increases. Lunches and dinners were also provided to B&B’s manufacturing workers, who work rotating three-day, 12-hour shifts.

With a large Spanish-speaking workforce — including many married couples and partners, and now even some of their grown children — B&B publishes all of its HR documents and newsletters in English and Spanish. Due to its HR policies, training programs, internal growth, and policies of promoting from within, B&B has also received two $250,000 Massachusetts state training grants, which include ESOL courses, computer and supervisory skills training, and equipment training programs for new team members. The end result has been a very low turnover rate and the employment of several multiple-generation families.

An existing, underutilized mezzanine space was also converted recently to create a $250,000 training and safety center, which is being used for ISO, G7, and 5S training; new employee orientation; OSHA safety training; and more.

‘Wall of Fame’ Is Big Hit With Workers, Clients

But Galligan is perhaps most proud of B&B’s Team Member Recognition Program that promotes innovation and continuous improvement in every department, including manufacturing, HR, scheduling, customer service, estimating, and more. If an individual employee or crew comes up with an idea or procedure that improves productivity or quality, or simplifies any workflow, the staff member and/or crew each receive $50 and have their pictures posted on B&B’s “Wall of Fame.”

“Team members love this program, which pays out close to $50,000 per year. It keeps them engaged looking for opportunities to improve our performance,” Galligan says. “Equally important, it increases productivity by close to $1 million annually. “And seeing the ‘Wall of Fame’ makes a big impact on clients when they come to our facility and realize the extent of our commitment to continuously improve quality and productivity,” he adds. “The feedback we get from our clients is that B&B’s quality, customer service, and lead times are top-notch.”

Galligan and his team also listen very carefully to its long-term clients and suppliers about where the book market is going, and how it can innovate and invest to meet their needs. A good example is B&B’s substantial investment in its four-color print platform and the addition of 200,000 sq. ft. of warehousing and distribution space to become a full-service supply chain partner for its publishing clients. For B&B, its customers, and team members, it seems that the best is yet to come.